Electronic Lead Screw (ELS)

The Finished Project:

Demo of Main Features:

Demo Cut Made For The Jet Engine Using The ELS:

It’s been 4 years since I built this project, it’s still installed on my lathe and it is without a doubt one of the most practical projects I’ve done. I can’t imagine using the lathe without this upgrade anymore.

The premise for this project was to replace the mechanical gearbox (shown below) of the lathe that is used to control the auto-feed rate with an electronic gearbox comprising of an encoder, motor and controller with which the gear ratio can be changed instantly rather than requiring a long changeover process to, for instance, cut a single point thread.

This is done using a Nema 23 stepper motor and rotary encoder which are controlled with a TI F280049 micro-controller which is capable of handling the very fast response times required to keep up with the potentially high rpm of the system.

The user makes inputs on a separate module containing and Arduino nano, 7-segment displays and complementary electronics which then communicates back to the TI micro-controller using a custom serial communication protocol.

The device supports threading and feeding modes with appropriate feed rates for each, allows for reversing the feed direction on the fly and allows for the stepper to be disabled completely at will.

The full code can be found here at the Github page for the project.

Gearbox Before Image:

(Without ELS Modification)

Making of the Project:

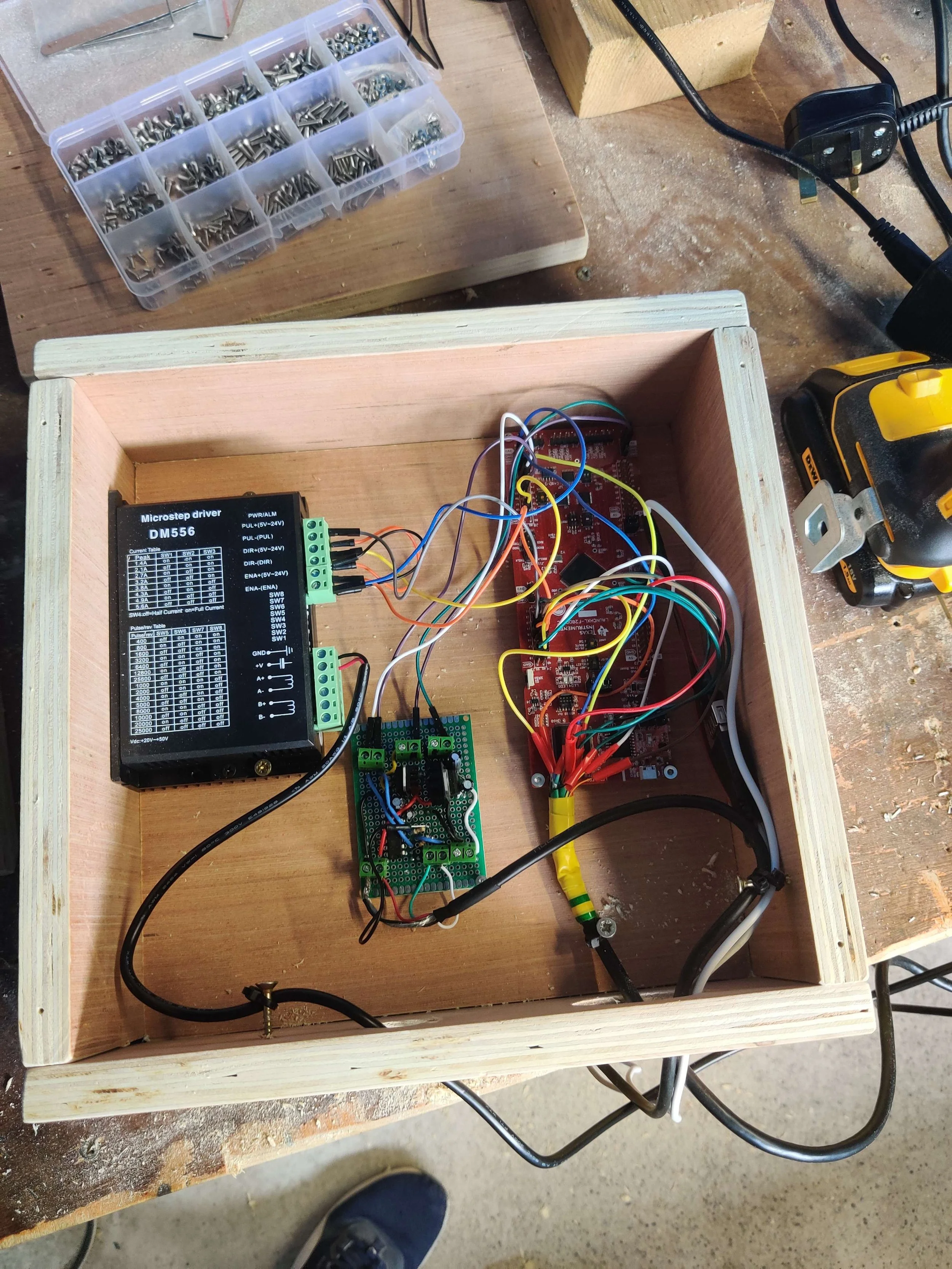

Creating the Electronics for the Control Box:

Creating the Encoder, Motor and Control Electronics:

Designing the Code for the System:

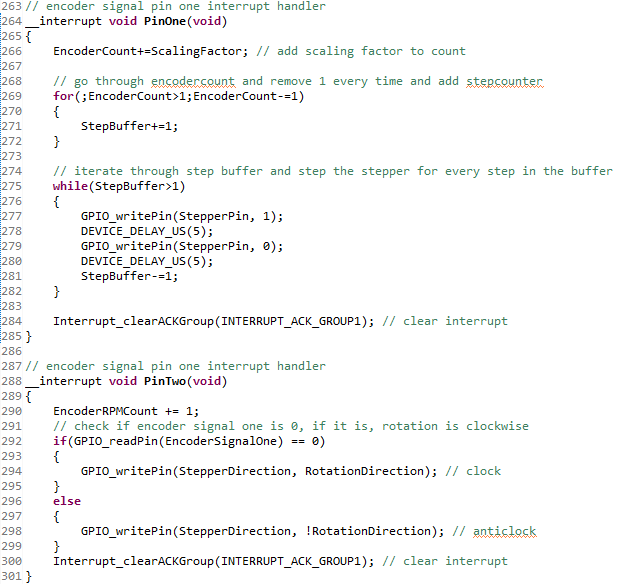

Code responsible for reading the encoder signals and turning the stepper motor accordingly:

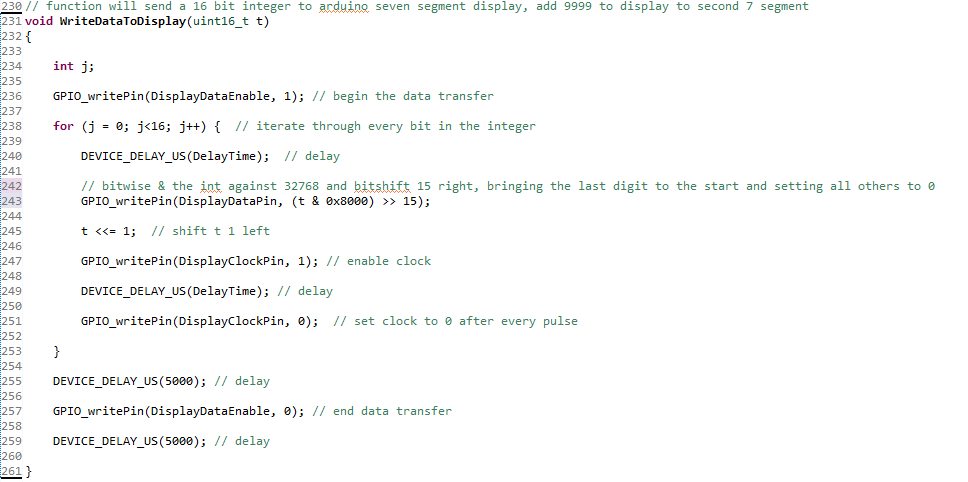

Custom serial communication protocol allowing the TI microcontroller to send 16 bit values to the Arduino

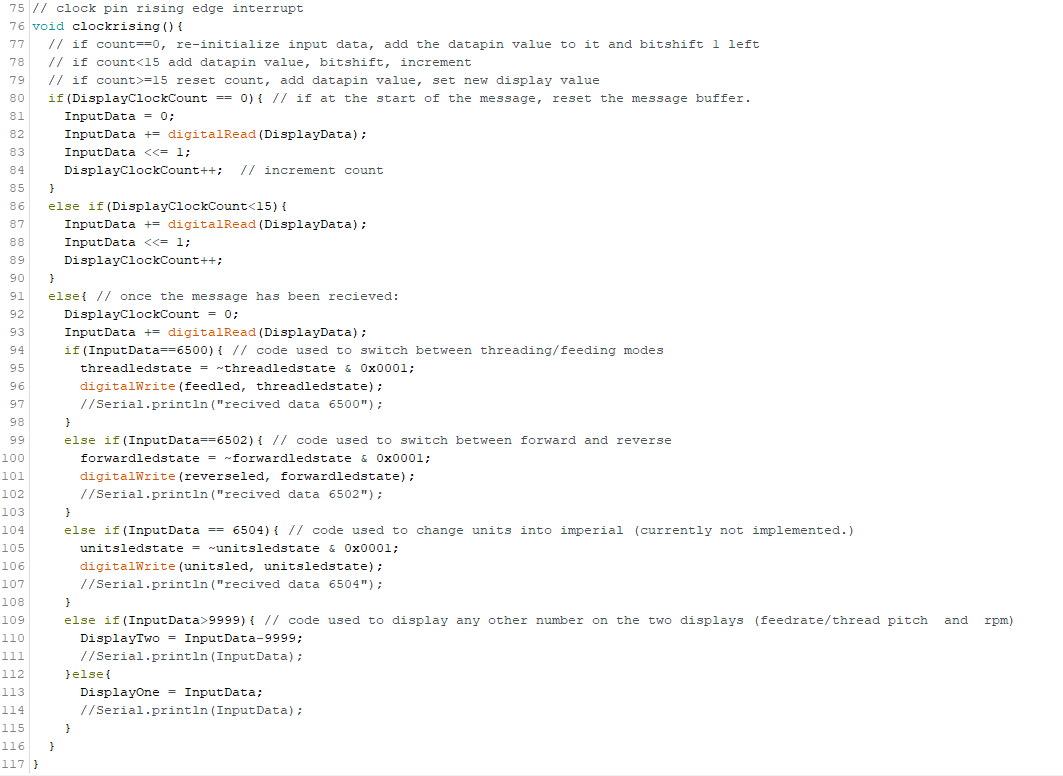

Arduino code which receives and processes those messages from the TI microcontroller: